Liquid Metal Engines: The Future of Automotive Power

The dawn of a new era in automotive engineering is upon us, heralded by the emergence of liquid metal engines. This groundbreaking technology promises to revolutionize the way we think about power, efficiency, and sustainability in the automotive world. Imagine an engine that can shape-shift, adapting to driving conditions in real-time, all while delivering unprecedented performance and fuel economy. This isn't science fiction—it's the cutting edge of automotive innovation, and it's closer to reality than you might think.

The alloy used in these engines is typically a mixture of gallium, indium, and tin, carefully formulated to maintain a liquid state at operating temperatures while offering excellent thermal and electrical conductivity. This allows the engine to rapidly adapt to changing load conditions, effectively becoming a shape-shifting powerplant that can optimize its performance on the fly.

Thermodynamic Magic: How Liquid Metal Engines Work

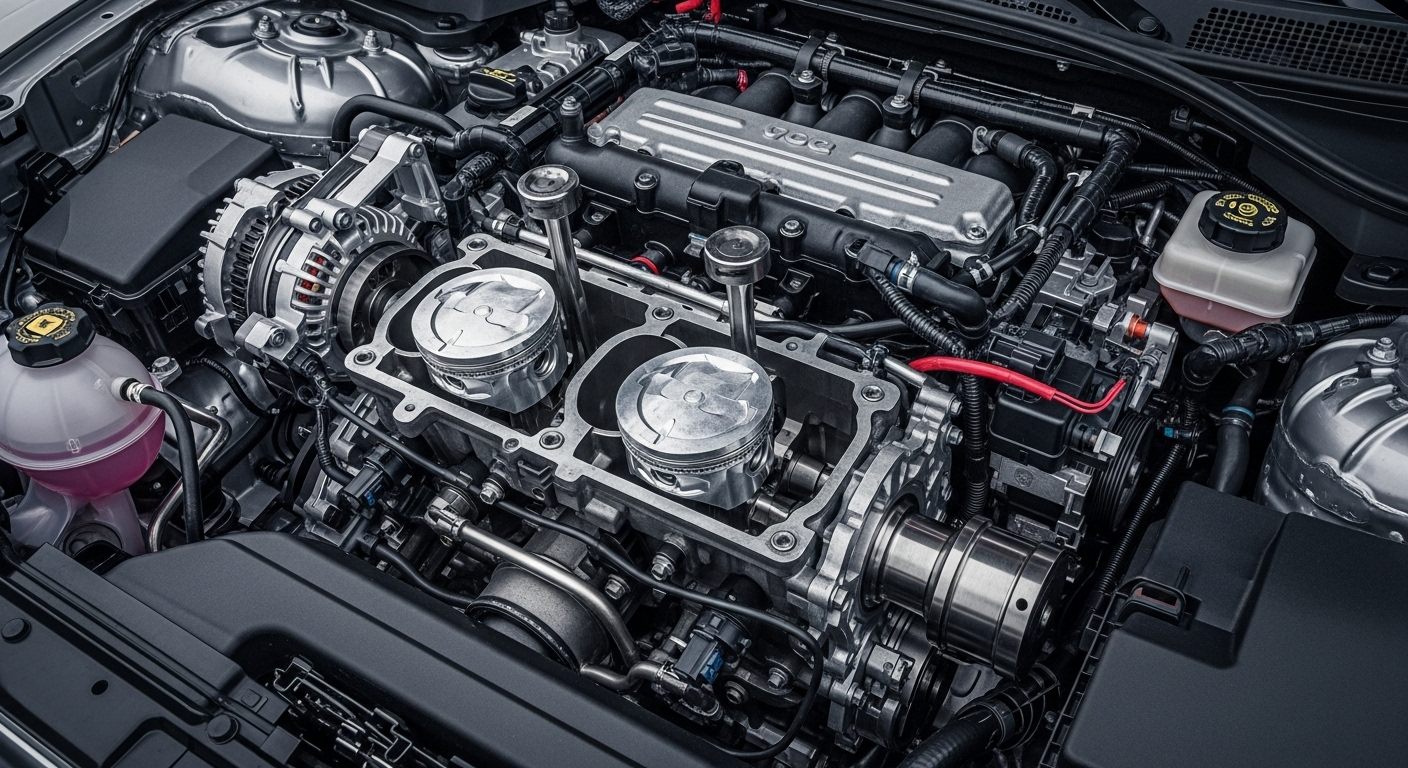

The operation of a liquid metal engine is a marvel of modern engineering. As heat is applied to the liquid metal core—either through combustion or external heat sources—it expands and contracts, driving a series of pistons or turbines. This process is remarkably efficient, as the liquid metal’s high thermal conductivity allows for rapid heat transfer and energy conversion.

One of the most intriguing aspects of this technology is its ability to capture and utilize waste heat. In traditional engines, a significant portion of energy is lost as heat. Liquid metal engines, however, can recirculate this thermal energy, significantly boosting overall efficiency. This closed-loop system not only improves fuel economy but also reduces emissions, making it a promising solution for environmentally conscious drivers and manufacturers alike.

Adaptive Performance: The Shape-Shifting Engine

Perhaps the most revolutionary aspect of liquid metal engines is their ability to adapt in real-time to driving conditions. By altering the flow and pressure of the liquid metal, these engines can effectively change their displacement and power output on demand. This means that a single engine could provide the fuel efficiency of a small four-cylinder during highway cruising, then instantly transform to deliver the power of a V8 when acceleration is needed.

This adaptive nature extends beyond just power output. The liquid metal’s rapid heat transfer properties allow for precise temperature control throughout the engine, optimizing combustion efficiency and reducing wear on components. The result is an engine that not only performs better but also lasts longer, potentially reducing maintenance costs and extending vehicle lifespan.

Manufacturing and Material Challenges

While the potential of liquid metal engines is immense, bringing this technology to market presents several significant challenges. The production of the liquid metal alloy itself requires precise control over composition and purity, as even small variations can dramatically affect performance. Additionally, containing and circulating the liquid metal within the engine requires advanced materials that can withstand high temperatures and pressures while resisting corrosion.

Engineers are also grappling with the challenge of sealing these engines effectively. Unlike traditional engines, where gaskets and seals are relatively straightforward, liquid metal engines require innovative solutions to prevent leaks while allowing for the necessary fluid movement. This has led to the development of new sealing technologies, including magnetically actuated seals and advanced ceramic composites.

The Road Ahead: Implications for the Automotive Industry

As liquid metal engine technology matures, its impact on the automotive industry could be profound. The potential for drastically improved fuel efficiency and reduced emissions aligns well with increasingly stringent environmental regulations. Moreover, the adaptability of these engines could lead to a new paradigm in vehicle design, where a single powerplant can serve multiple vehicle types and driving styles.

The integration of liquid metal engines into existing manufacturing processes will require significant investment and retooling. However, the long-term benefits in terms of performance, efficiency, and sustainability may well justify the initial costs. As automakers race to develop and patent liquid metal engine technologies, we may see a shift in the competitive landscape of the industry, with those who master this technology gaining a significant edge.

A Fluid Future for Automotive Power

Liquid metal engines represent a bold step into the future of automotive technology. By harnessing the unique properties of these exotic alloys, engineers are creating powerplants that are more efficient, adaptable, and sustainable than anything we’ve seen before. While challenges remain in bringing this technology to market, the potential benefits are too significant to ignore.

As we look to the horizon of automotive innovation, it’s clear that liquid metal engines could play a crucial role in shaping the cars of tomorrow. Whether powering sleek sports cars or efficient family vehicles, these shape-shifting marvels promise to redefine our expectations of what an engine can do. The road ahead is fluid, and the future of automotive power has never looked more exciting.